To help clarify distinctions between Hypertherm heavy industrial plasma product offerings, specifically the XPR300® and the HPR400XD®, we wanted to provide information that will help guide your recommendations to customers, so they get the best option for their applications. Although the XPR is Hypertherm Associates’ current high definition cutting platform, the HPR400XD remains a very viable product for thick metal applications.

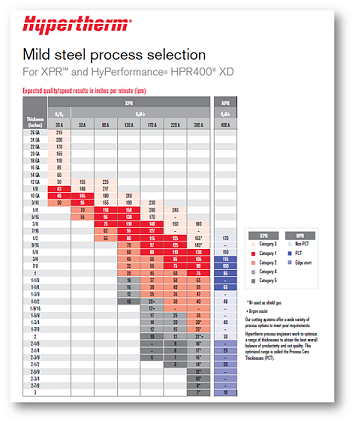

Our mild steel process selection guide is intended to allow customers to easily visualize the best plasma process (or processes) available for a specific mild steel thickness. This tool can help you, our partners, determine whether an HPR400XD or XPR300 cutting system best meets specific customer cutting requirements.

The zones highlighted in red in the table indicate the preferred range of operation for XPR systems. Hypertherm Associate process engineers work to optimize a range of thicknesses to obtain the best overall balance of productivity and cut quality also referred to as the “sweet spot”. This optimized range is called the Process Core Thicknesses (PCT): Category 1 for XPR and PCT for HPR.

The document can also be used to provide a guideline of what system is better suited for specific thickness ranges for example:

• If a customer is looking for a well-rounded system that has the versatility of cutting a wide range of thicknesses from thin gauge to occasional thick mild steel above 36mm ~ (1-1/2 in), then an XPR300 will be the best choice.

• If a customer is planning to cut mostly thick mild steel above 31mm ~ (1-1/4 in) then, an HPR400XD will provide the necessary power to tackle those jobs.

Important notes:

• Every customer is different, so understanding their specific needs and expectations is important to recommend the appropriate system configuration and plasma process to fulfil their needs.

• Thickness capability is NOT the only factor that should be considered when offering a system. The customer’s plans for expansion, on-site input power, non-ferrous cutting versatility and desired cut speeds are also important to consider when recommending a system.